|

|

#1 |

|

Участник

|

Sumit Potbhare: How Batching Orders Saves Operating Cost? | Approach to D365 for Commerce with Adv WH Mgmt

Источник: https://sumitnarayanpotbhare.wordpre...h-adv-wh-mgmt/

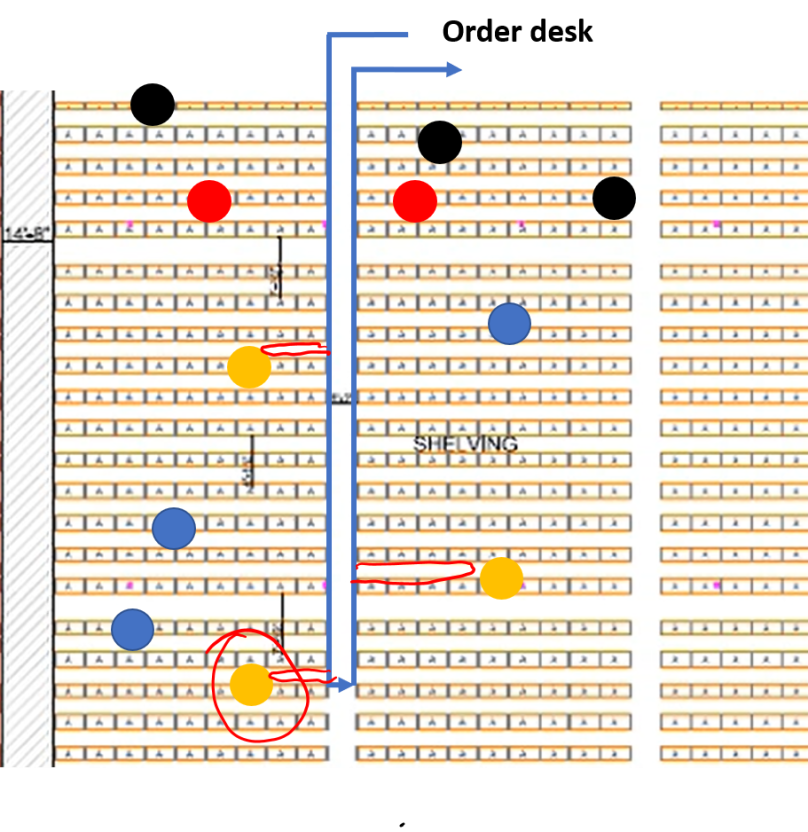

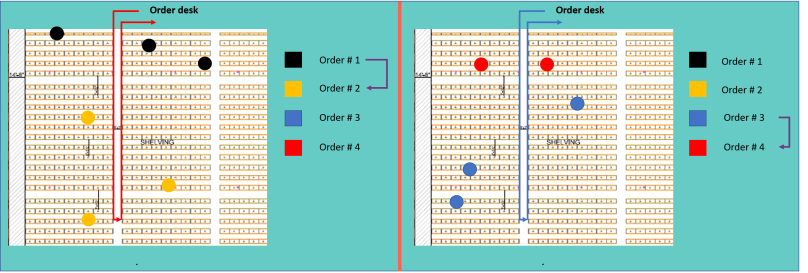

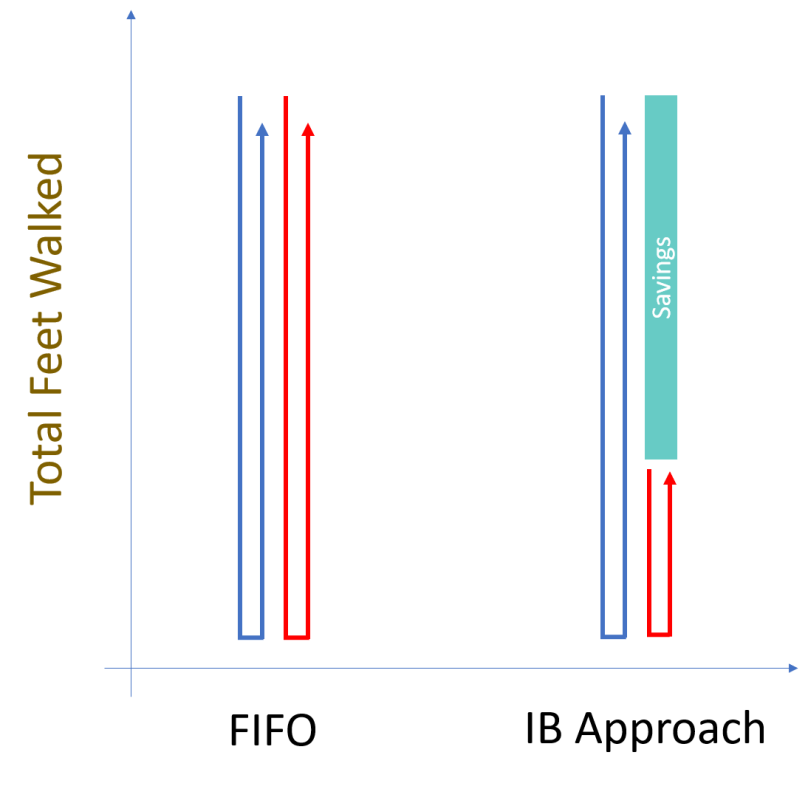

============== Hi Guys, In our previous blog we have started another series to talk about how we can save cost in different Retail Warehouse operations involved. Now its time to see them one by one. In this blog, we are going to see probably the most important or most significant way that you can help a Retail Warehouse operation reduce its costs by figuring out better ways to batch orders in such a way that they travel less.  For example, in this picture, you can see a cart that has 12 orders/totes. Each tote on this cart pertains to one order. Well, the question is: What 12 orders should you put together on that cart and pick together? As we will see in the next little sequence, your labor can be quite different based on which orders you pick. So imagine here we are, we’re looking down on a forward pick area. And notice there’s the order desk up here at the top. That’s where they get their pick tickets from. And let’s further imagine that we have four orders that have just come in. And those orders have picks that are distributed across various places in the warehouse.   And so now let’s just imagine that we want to pick order #2. You can see we leave the order desk, come down to the last aisle, and as we are going along, we’d make these side trips. We’d come over, make first pick on the left and come down to pick second, and then third on the way back on the right side and then go all the way back to the order desk. If anyone is picking order one at a time, he/she would pick in that fashion. So the further is the last pick down, the last row of a given order is going to drive how much we have to walk up and down through the main travel aisle there. But let’s say then we have a cart that doesn’t hold 12 totes; it only holds two. So the question now is: Which two orders should we batch together on one cart, and which two orders should we batch on the second cart, if what we want to do is reduce or minimize the amount of walking that we’re going to do. So let’s figure that out. One Way To Do It : FIFO The most common way to batch two orders together on a cart will be in FIFO sequence. In other words, the way in which they get downloaded or get entered into the system is the sequence in which they get picked. So if we were to do that, and pursue a FIFO approach, we would end up batching orders 1 and 2 together.  And so you can see the picks here. So the pick path would look something like this. We go all the way down there to the second to end of the aisle and then all the way back to order desk. And then we would batch order #3 and order #4 together. And so we would go on another one of these long pick paths, not quite as long, maybe one aisle short. But still a pretty long pick path. And so you can see the picks here. So the pick path would look something like this. We go all the way down there to the second to end of the aisle and then all the way back to order desk. And then we would batch order #3 and order #4 together. And so we would go on another one of these long pick paths, not quite as long, maybe one aisle short. But still a pretty long pick path. One Way To Do It : Intelligent Batching Now let us look at the next method, which is called intelligent batching, and lets see how we can reduce this travel, if we’re smart about how we batch these orders together. So let’s think about batching these orders together into pick carts or pick tours that really make sense or minimize the amount of travel.  Well, if I had my opportunity to choose any two orders to pick together, I think that the first ones that I would like to pick together would be #1 and #4, because they finish pretty much in the same general area of the forward pick area. They don’t have any picks way in the back. If I want to pick those, I’ve just got to go on this short tour and I’m done. Now, that means, we would have to pick 2 and 3, and that would be one of those longer pick tours because I would have to go back there to the second to last aisle. But 2 and 3 generally finish in the back half of the warehouse. That means I only have to go back there once. Well, if I had my opportunity to choose any two orders to pick together, I think that the first ones that I would like to pick together would be #1 and #4, because they finish pretty much in the same general area of the forward pick area. They don’t have any picks way in the back. If I want to pick those, I’ve just got to go on this short tour and I’m done. Now, that means, we would have to pick 2 and 3, and that would be one of those longer pick tours because I would have to go back there to the second to last aisle. But 2 and 3 generally finish in the back half of the warehouse. That means I only have to go back there once.  So if you look at what this does to the total feet walked is that the intelligent batching approach generates two pick paths. One that’s really long for that orders 2 and 3, and then one that’s kind of short for the ones that were orders 1 and 4. And this compares pretty favorably to the two tours that both were very long for the FIFO approach. So you can see where the savings starts to accrue. And the savings can be significant if you have lots of orders and lots of aisles, you can have a lot of orders that would, if you pick in FIFO, or pick carts almost always have to go all the way to the back. But if you consider this intelligent batching approach, you can get a lot of pick carts that don’t go back to the first, second, third, fourth aisle in the whole forward pick area. So you can save a lot of labor. Just how much is what we will see about next. So What’s This Worth? These are some simulations of actual orders through a forward pick area for a e-commerce company; and this is comparison of the base situation, which is the FIFO batching, with intelligent batches that are chosen really in a smart way.  This also compares singles with multis. And you can see that at a base of 25 pickers, just singles versus multis saved $380,000. But going even further, and doing what we saw before, intelligent batching, we get $590,000 out of that 25 pickers. That’s a huge amount of money. And you can see, if you have a base of 50, it’s even more. So this is one of these really, really important things to consider. And D365 FO allows us to do this. And it allows us to do the intelligent zone batching. It’s a little bit different than you would expect, but it does let us do that. So now the obvious question that probably is on everybody’s mind is how do we do that. This also compares singles with multis. And you can see that at a base of 25 pickers, just singles versus multis saved $380,000. But going even further, and doing what we saw before, intelligent batching, we get $590,000 out of that 25 pickers. That’s a huge amount of money. And you can see, if you have a base of 50, it’s even more. So this is one of these really, really important things to consider. And D365 FO allows us to do this. And it allows us to do the intelligent zone batching. It’s a little bit different than you would expect, but it does let us do that. So now the obvious question that probably is on everybody’s mind is how do we do that.So How Can We Implement This?  Presorting Pick Worksheets into Clusters Presorting Pick Worksheets into ClustersYears ago most people in many warehouses around the country picked with paper. And when they did that, there was somebody like this woman in the picture who sorted all of the various pick lists in such a way that those pick lists that needed items that were kind of in the same general area of the warehouse were kind of batched together, and they’d be handed out in the stack to a picker and you’d be sent over to the corner of the warehouse where most of those warehouse orders needed to be picked. So this doesn’t happen as much anymore, because, first of all, most picking in many warehouses is done with mobile device terminals. Not all, but there’s still a lot of places like the paper pick, but there’s still many more that like to pick with mobile device terminals. The second thing is most warehouses let the system essentially perform this activity that this lady is doing. The system builds the clusters for the pickers, not a human. Because they’re serving those clusters of orders to the pickers through the mobile device terminals. The issue, though, is that the way in which most warehouses do that or cluster those orders together is they use that FIFO methodology. Interesting enough, this approach that you see here is the one that D365 FO uses to build the clusters. There’s a step, the system doesn’t automatically build the clusters. It requires that a human put together the list of orders that the picker needs to pick together. And so there’s this first step of creating the cluster followed by a picking process of executing the picks associated with the cluster.  So what you usually get when you start a wave is you’re going to get a bunch of these work order sheets. I’m thinking they might become a packing slip for some places. But you get these pieces of paper and the way that you build a cluster is we saw in the video in our earlier blog is you just scan all the work order IDs for the orders that are going to get picked together. If you need 12, then you scan 12. And that creates a cluster. Because this then is essentially nothing more than a report. There’s a great opportunity for partners to create logic that sorts these things in such a way that this person could build really, really smart and intelligent and short pick clusters in such a way that’s really better than any software logic could do it. But it just basically requires some thought and you need to sort these things out in such a way that the orders that shouldn’t be picked together, like Rush vs Normal shouldn’t be picked together, VAS versus No VAS shouldn’t be picked together. But you can add up the cube information up here to the report so that the person that’s doing the cluster building can sort by order cube or can see that these orders are small so they can go on the cart that has the small totes versus the ones that are big can go on the carts that have the big totes. You can sort by the last aisle visited by the order, and you could add that also to the report. You could put the last aisle on it. So that would help build those really shorter pick tours that we saw earlier. So what you usually get when you start a wave is you’re going to get a bunch of these work order sheets. I’m thinking they might become a packing slip for some places. But you get these pieces of paper and the way that you build a cluster is we saw in the video in our earlier blog is you just scan all the work order IDs for the orders that are going to get picked together. If you need 12, then you scan 12. And that creates a cluster. Because this then is essentially nothing more than a report. There’s a great opportunity for partners to create logic that sorts these things in such a way that this person could build really, really smart and intelligent and short pick clusters in such a way that’s really better than any software logic could do it. But it just basically requires some thought and you need to sort these things out in such a way that the orders that shouldn’t be picked together, like Rush vs Normal shouldn’t be picked together, VAS versus No VAS shouldn’t be picked together. But you can add up the cube information up here to the report so that the person that’s doing the cluster building can sort by order cube or can see that these orders are small so they can go on the cart that has the small totes versus the ones that are big can go on the carts that have the big totes. You can sort by the last aisle visited by the order, and you could add that also to the report. You could put the last aisle on it. So that would help build those really shorter pick tours that we saw earlier. This is just one way that by using partner functionality combined with the base product we can really kind of flip what some people might say is a disadvantage of having a warehouse operator that has to get involved to build the clusters into a strength and then by creating clusters that are very, very efficient. In our next blog we will take a look at another way that you can save picker time with some base out-of-the-box but unusual functionality from D365 FO. Feel free to reach out for any clarifications. If you like my blog posts then comment and subscribe to the blogs. Join 107 other followers Email Address: Subscribe #RetailDAXing #D365Commerce Disclaimer: The information in the weblog is provided “AS IS”; with no warranties, and confers no rights. All blog entries and editorial comments are the opinions of the author. Credits: Microsoft Learn, Microsoft Docs Источник: https://sumitnarayanpotbhare.wordpre...h-adv-wh-mgmt/

__________________

Расскажите о новых и интересных блогах по Microsoft Dynamics, напишите личное сообщение администратору. |

|

|